Transforming Mobility: How Low-Voltage Battery Architectures Are Helping Shape the Software-Defined Vehicle

By Federico Morales-Zimmermann, Group Vice President and General Manager, Original Equipment & Technology at Clarios

In the coming decade, vehicles will undergo more transformation than they have in the past century, driven by unprecedented advancements in technology and sustainability. This transformation isn't just about the vehicles themselves; it extends to the very heart of what powers them - the batteries.

Every Vehicle Including Internal Combustion, Hybrid and Full EVs Need a Low-Voltage Power Source

When you mention automobile batteries today, many people immediately think of the large Lithium-Ion batteries found in EVs. That’s only part of the story. Vehicles, including EVs, need a power source to get them started, to power lights, displays, and safety and autonomous features. These low-voltage batteries are the backbone of the electrical system in modern vehicles. And as we look to the future, they are playing an increasingly important role in vehicles.

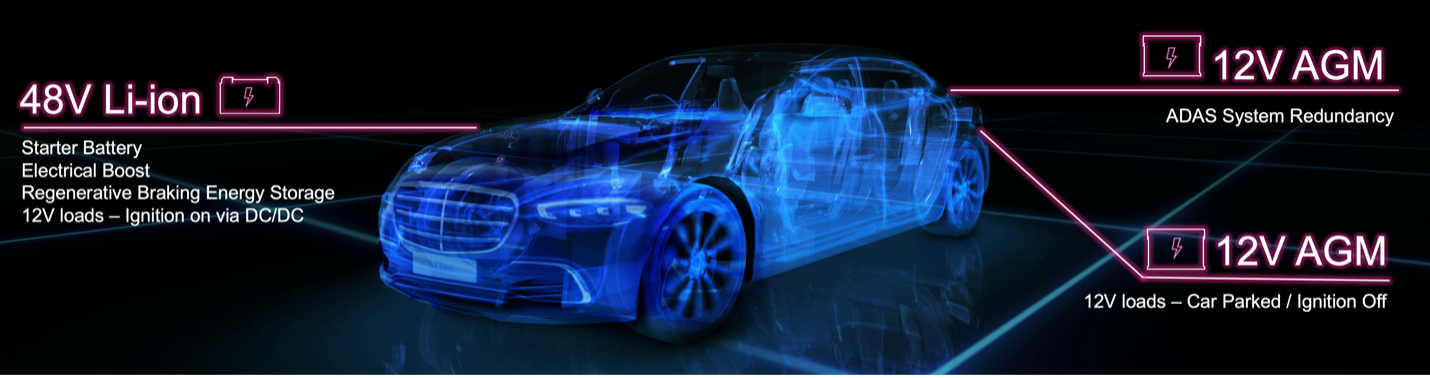

As an example, today’s leading luxury sedans often contain not one low-voltage battery, but in some cases as many as three. These low-voltage power sources power automated cruise control systems, over-the-air software updates, provide storage solutions for the energy saved with regenerative braking. At Clarios we’re all in to support the low-voltage system needs of our customers, and we’re excited by the direction technology is taking.

Clarios Is the World Leader in Low-Voltage Battery Systems, Empowering the Software-Defined Vehicle

Vehicles are moving from straightforward mechanical machines to complex, software-defined systems. By 2030, cars will be powered by over 300 million lines of code, a significant jump from the 100 million in 2020 and a stark contrast to the 1970s when cars had virtually no code. This shift demands an innovative low-voltage architecture capable of handling the complexity and power requirements of these advanced vehicles.

At Clarios, our goal is clear: to develop and expand multi-battery systems. These systems are designed to not just power vehicles but also to support their increasingly sophisticated functionalities. Even as the world leader, we recognize we must add new knowledge and capabilities to support our customers. Our recent acquisition of Paragon's battery business unit in Germany is one example of how we’re enhancing our capabilities in software, electronics, and systems integration, accelerating both our progress and customer program development.

The shift from mechanical to electrical systems has heightened the significance of the low-voltage network and its batteries, leading to the emergence of software-defined low-voltage architecture. Recognizing the challenges faced by OEMs as systems grow increasingly complex and sophisticated, it's become crucial to thoroughly understand electrical and electronic architectures to develop and offer the most valuable solutions.

Electrification and Digitalization Enables the Software-Defined Vehicle

As vehicles evolve from mechanical to electrical systems, the necessity for redundant power solutions becomes essential. Automakers are now developing technologies like steer-by-wire, brake-by-wire, and active chassis components, enhancing vehicle performance, reducing weight, and boosting efficiency. This change mirrors what we see today in modern airliners - dual-battery systems for safety. At Clarios, we're expanding our offerings to include such multi-battery networks and incorporating supercapacitors to enhance our low-voltage system solutions.

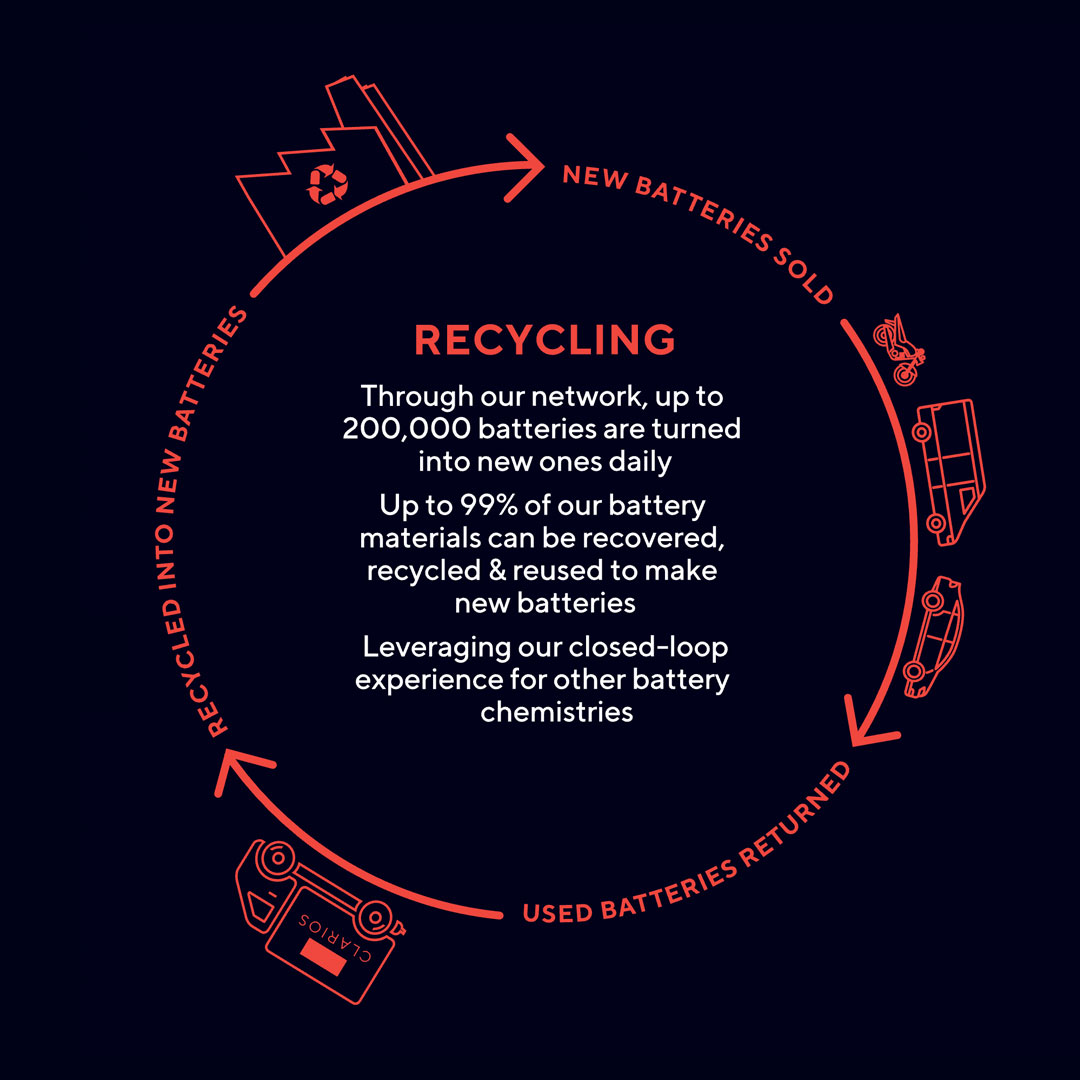

We’re partnering with automakers to navigate this transition, offering advanced low-voltage battery solutions and pioneering circular economy practices for automotive batteries, making us a leader in sustainable battery innovation. We're not just preparing for the future; we're actively shaping it with our comprehensive, integrated approach to low-voltage systems.

A Chemistry-Agnostic Approach to Vehicular Batteries

Not every battery that can be used with vehicles is created equal. In fact, vehicular batteries can be made with different chemistries. We can build them out of materials like Lithium Titanium Oxide (LTO), Lithium-Ion Phosphate (LFP), Nickel Manganese Cobalt (NMC), Sodium-Ion and Lead Acid. Sounds super complicated? In a sense it is. But what you really need to know is that these different chemistries give you batteries with different qualities. Some typically run longer, some have higher power for a shorter period time, some are heavier, and some are impacted by the outside air temperature. No one chemistry is better than another when making batteries for vehicles, it really comes down to the application.

Our approach is chemistry-agnostic – meaning we can work with any chemistry. This ensures flexibility and adaptability and allows us to focus on the needs of the vehicle our customer is developing. And we’re committed to this approach. It’s why we recently announced a collaboration with Altris, a Swedish company specializing in sodium-ion technology, to develop a sodium-ion-based battery solution for vehicular use. Our collaboration with Altris marks a pivotal step in our chemistry-agnostic approach. Through this partnership, we are at the forefront of developing low-voltage sodium-ion batteries, a technology inherently sustainable due to its composition of recyclable elements like salt, wood, iron, and air.

Traditionally, sodium-ion batteries have faced technical challenges, but our collaboration aims to overcome these obstacles. By harnessing the numerous advantages of this technology, such as the abundance and accessibility of raw materials, we are working towards creating a new generation of low-voltage batteries that are not only cost-effective but also more sustainable.

The Clarios Advantage: An Advanced Low-Voltage Systems Approach

Our advanced low-voltage systems approach is all-encompassing. We integrate chemistry, electronics, software, and diagnostics to provide the best solutions, irrespective of voltage requirements. Our global footprint allows us to distribute our wide range of products, including 12 to 48-volt solutions, to OEMs and the aftermarket globally.

Circularity and sustainability are embedded in Clarios' DNA, shaping our approach from design and product development through to production. We're committed to providing circular solutions, making our approach unique in the industry. With over 150 million batteries provided worldwide each year, our goal is to continue leading the transformation in the automotive battery space, helping to ensure future vehicles are powered by efficient, sustainable, and safe multi-battery systems.